On April 10, the American Galvanizers Association (AGA) announced the winners of the 2024 Excellence in Hot-Dip Galvanizing Awards during their Annual Conference in St. Thomas, USVI. Over 100 projects were submitted, representing various applications for hot-dip galvanizing. The finalists were judged online by a panel comprised of architects and engineers. An Algonquin Modular Bolted Truss Bridge that reconnected the community of Mira Gut in Cape Breton, Nova Scotia, won in the Bridge & Highway category.

The new galvanized bridge replaced an old steel swing bridge that had spanned the mouth of the Mira River for over 100 years. By 2017, it had rusted so badly that it was closed to all traffic and torn down, leaving the close-knit community separated and dealing with a 20-minute detour for a few years.

In considering the replacement bridge, there was a resounding choice that made all the difference in this oceanside setting — hot-dip galvanizing. A galvanized bridge was chosen for all of the right reasons: aesthetics, durability, sustainability, turnaround time, corrosion performance and life cycle cost. Aligning perfectly with the customer’s vision of creating a span that would stand the test of time, a partnership between the customer and galvanizer produced a streamlined project from start to finish.

Partnership with leading galvanizers was key

Once awarded the project by the Nova Scotia Department of Public Works, the Algonquin Bridge team partnered with galvanizers Valmont Coatings and Pure Metal Galvanizing to hot-dip galvanize all of the modular bridge system’s steel components. As the components were fabricated at Algonquin’s Thorndale, Ontario, facility, they were shipped over to the galvanizers in stages. The galvanizers were able to meet our strict turnaround times and deadlines for the project, ensuring the customer received a quality product that would stand for 100 years or more with minimal maintenance.

Take a 360° drone-video tour of this project through assembly, cantilever launch and completion >>

Aesthetics were also an integral part of the overall project. Hot-dip galvanizing not only offered superior corrosion protection, but also a pristine, matte finish that enhanced the bridge’s features. Hot-dip galvanizing also ensured the structure would be resilient against corrosion, extending its life and reducing the need for costly maintenance.

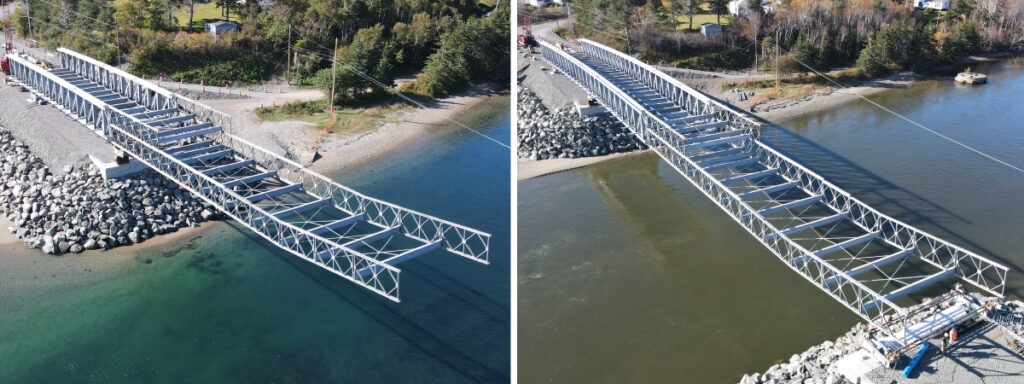

The bridge system was delivered on flatbed trucks, assembled on-site and deployed using the cantilever launch method from one side of the river. Kudos to our other project partners, Northern Contracting Limited as the general contractor and Leslie & Benn Contracting Ltd. as the bridge erector. It was great working with these teams.

New bridge opens to great fanfare

On a sunny day in August of 2022, the community gathered to witness and celebrate the opening of their new bridge. Watch this great CTV News Video on the grand opening event featuring: a 94-year-old woman who mused about jumping off of it, “Bridge Man Bob” who manually operated the old swing bridge for passing boats for over 36 years and hundreds of residents happy to be reconnected to each other.

About Algonquin Modular Bolted Truss Bridge Systems

For heavier-duty applications, Algonquin Modular Bolted Truss Bridges use innovative 2.25 m long panels that are bolted to top and bottom chord members to form pre-cambered side trusses that carry the applied loads and counter dead load deflection.